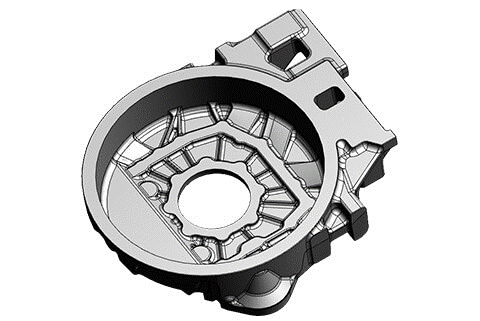

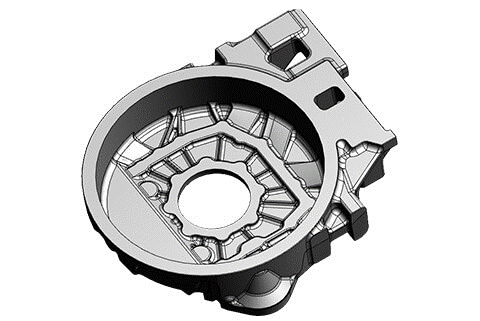

Flywheel Housing for Consturction Machinery

What is a flywheel housing?

The flywheel housing, also known as a bell housing, is a component of an internal combustion engine used to encase the flywheel and connect the engine to the transmission.

Functions of the flywheel housings

The flywheel housing serves as a protective casing for the flywheel, facilitating the connection between the engine and the transmission. Additionally, it provides necessary support and protection for the flywheel, clutch assembly, and transmission components.

Machining techniques required for producing flywheel housings

Mechanical machining techniques such as turning, milling, drilling, tapping, and thread cutting are commonly used in the production of flywheel housings.

Key features in the production of flywheel housings

As a component designed to protect the flywheel, the raw material hardness must meet specified standards. There are specific requirements for hole diameter, perpendicularity, and positional accuracy. During the machining process, mold verification, tool lifespan management, tool holder periodic checks, and statistical process control (SPC) are employed to achieve the required precision.

Conclusion

World Known Precision Industry (WKPT) has years of experience in manufacturing powertrain components for foreign vehicle and machinery systems, including gear housing and flywheel housing. Through well-planned mechanical machining processes, the material's mechanical properties and precision requirements for these components can be met. If you have machining needs for power system components, feel free to contact WKPT to complete the production of power system components.

Copyright © bizWINNER 2024